Drivers are getting a serious grip at 14 high-collision locations throughout the Lower Mainland and Vancouver Island with the application of high friction surface treatment.

High friction? Yeah, basically the roads at four interchange off-ramps and 10 intersections are getting coarser to reduce skidding, and thus, decrease braking distances.

Here’s how it works: using an automated truck-mounted machine, crews lay down specialized aggregate overtop a resin binder. The type of aggregate is called calcined bauxite, which is extremely hard and retains the sharp edges produced from crushing – a combination that provides a big boost to skid resistance.

Watch contractor DBI Services in action:

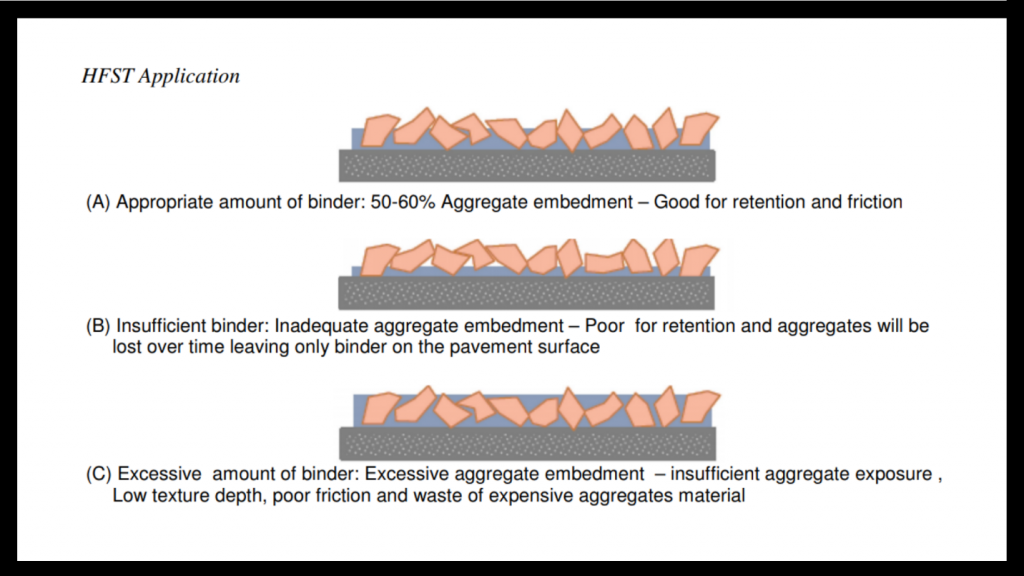

As you can see below, crews must hit the sweet spot when laying down the binder – too little, and it won’t hold the aggregate in place; too much, and there won’t be enough exposed aggregate to come in contact with, and help stop, rolling tires. Think of it as the Goldilocks principle.

The applications are 150 metres to 250 metres, long depending on the location, and the distances were determined based on where typical traffic queues form and vehicles begin braking.

We partnered with ICBC to identify the 14 locations based on a review of collision and claims data:

Lower Mainland

- Highway 1 – Capilano Road off-ramp (westbound) in North Vancouver

- Highway 1 – Lonsdale Avenue off-ramp (eastbound/westbound) in North Vancouver

- Highway 1 – Willingdon Avenue off-ramp (eastbound) in Burnaby

- Highway 1 – Brunette Avenue off-ramp (eastbound/westbound) in Coquitlam

- Highway 7 – 203 Street intersection (eastbound) in Maple Ridge

- Highway 7 – 207 Street intersection (eastbound) in Maple Ridge

- Highway 7 – Kennedy Road intersection (eastbound/westbound) in Pitt Meadows

- Highway 7 – Laity Street intersection (eastbound) in Maple Ridge

- Highway 10 – 120 Street/Scott Road intersection (eastbound/westbound) in Surrey

- Highway 10 – 176 Street intersection (eastbound/westbound) in Surrey

Vancouver Island

- Highway 17 – Cloverdale Avenue intersection (southbound) in Saanich

- Highway 17 – Elk Lake Drive intersection (northbound/southbound) in Saanich

- Highway 17 – Sayward Road intersection (northbound) in Saanich

- Highway 17 – Mt. Newton Cross Road intersection (northbound/southbound) in Saanich

Friction between tire and road is such an important factor for stopping vehicles quickly. This surface treatment could have a significant impact in reducing collisions, especially in wet conditions and high-speed situations. This initial round of high friction surface treatment is being done as a pilot. We’ll evaluate its success before considering its application at other locations.

Have you driven on this surface treatment yet? What was it like? Let us know in the comments below.

Hello. We did the similar idea on the road between Terrace and Prince Rupert with Williamson Blacktop We used a mix of 100% Fracture 12 mill aggregate , lay down with paver over proper tack coat (ss1 ) rolled with are rubber tired roller.

Is that not, at one time, called sealcoating? Chip sealing. Spray HF150 usually .36 gallons per square yard and then the chip spreader lays down the aggregate that at one time was called G.A.S. material. I may be mistaken but that looks similar to what I have seen before. Why did chip sealing disappear?

Hi Grant,

Thanks for your question. We do still do sealcoating (here’s a link outlining: https://www.tranbc.ca/2015/05/14/what-is-sealcoating-and-why-are-we-doing-it-on-bc-highways/). High Friction Surface Treatment uses a resin application which makes it slightly different. Hope this information is helpful.

Razor blade surface is not so good for tires and human flesh but no one calling the shots has figured this out yet. Should add to the number of vehicle roll overs also. Nice images of road surfaces.

Hi William. High friction surface treatment is only applied at select, high-collision intersections and off-ramps, so excessive tire wear should not be a problem. The application toughens the road surface to reduce skidding and helps vehicles come to a complete stop, quickly and safely.

is this surface just where the cars drive and is it easy for scooters and powerchairs to bypass when using treated intersections

Hello Trevor and thanks for your message. This application is only in the travel lanes up to the stop bars, there is no treatment applied to the crosswalks, the shoulders of the road or in the middle of the intersection. We hope that this helps clarify!

While I think this is a great idea, every little bit helps!! Especially on the Pat Bay Highway. There is simply too much traffic for the highway to manage safely. I’m am confused though as to why you would not have done the southbound lanes at Sayward on the Pat Bay Highway. There are just as many fender benders and close calls in the southbound traffic especially when there is ferry traffic. As someone who’s been driving this highway southbound Monday to Friday at 8:00am and northbound at 4:30pm for 40+ years I’ve seen a lot of accidents and near misses as this intersection. I myself have a family member who was rearended there.

I urge you to reconsider your decision not to do the sounthbound lanes and get them done ASAP.

Hi there concerned driver and thank you for your message. We sent your comment to the staff responsible for the project and they let us know that in selecting the locations for this pilot project MOTI teamed up with ICBC to select the highest collision locations that would benefit from the treatment. The work is now complete, however the ministry will be monitoring the applications so that it’s use can be considered at more locations in the future. They are reaching out to ICBC for more information about how a decision was made on Sayward southbound vs northbound. We will let you know what we hear back.

Hello again Concerned Driver!

The project team just let us know that ICBC reviewed the north and southbound sections and determined that the potential safety benefit or collision reduction in the southbound direction is less for this counter-measure compared to other locations. As this is a pilot project – we are monitoring it closely to see if more sections could benefit in the future. We hope that this helps answer your questions. Safe travels.

I have driven on the new surfaces coming down the Pat Bay highway and it appears to me that the mix may not be correct as detailed above. The first time I drove on this with my motorcycle in shorts I was bombarded by little debris that felt like little rocks and it took me a few days to figure out what it was. When I put my foot down at Cloverdale and Blanchard my foot slipped so I looked down and saw that there was a layer of fine black sediment. This fine sediment is not rally conducive to a safer ride as it is more like a fresh dusting of flour on a bakers table meant to stop things from sticking.

Hello Wayne and thanks for your comment about the High Friction Surface Treatment. We did hear some concerns about gravel on the road initially after the treatment was applied and had our crews return to do multiple sweeps and vacuums of the areas. Could you tell us if you still notice an area of concern? We would like to follow up if so. Thank you.

The southbound bike lane along Blanshard is full of awful fine gravel thanks to this nonsense. If you really want to calm traffic on this non-highway road, road diets and protected bike lanes are the way to do it, not this waste of time!

MOTI should not be in the business of managing urban roads, anyway. You really aren’t very good at it, you keep thinking they’re highways in the middle of nowhere.

Please sweep Blanshard in the next day or two, it’s hazardous and awful right now.

Hello Irritated YYJ Cyclist,

We reached out to the project team who helped deliver the High Friction Surface Treatment works. They informed us that a vacuum sweeper makes multiple passes, after the product has cured, to pick up the loose bauxite aggregate, The treated surface is then examined by the work crews. They know the shedding issue, and do their best to remove as much as possible prior to opening the road to traffic. It is a normal for there to be shedding after the surface is driven on. The loose material is thrown by the traffic to the sides and carried downstream onto the untreated surfaces.

A secondary clean-up is required to be performed three to five days after construction, but the contractor generally will sweep the next shift, and succeeding shifts, to pick up the shed material.

We hope that this helps to answer your concern.

Horrified as I drove over this surface and small rocks are flying everywhere!!! Rocks flying at me from the cars in front of me. I’ve driven over 3 places and it’s all the same. It’s worse than driving over a gravel road. The rocks stuck to my tires and flung off after. I could hear them hitting my car from the cars in front of me. What if I was a pedestrian or cyclist? Or in a convertible? It seems like a crazy road surface to me.

Hi there Shocked Driver,

Have the roads been recently treated? There may be small rocks on the surface, which will adhere after application. Could you tell us where you noticed this? We would like to follow up.

Hi there again shocked driver. We reached out to the project team who helped deliver the High Friction Surface Treatment across the Lower Mainland. They informed us that a vacuum sweeper makes multiple passes, after the product has cured, to pick up the loose bauxite aggregate, The treated surface is then examined by the work crews. They know the shedding issue, and do their best to remove as much as possible prior to opening the road to traffic. It is a normal for there to be shedding after the surface is driven on. The loose material is thrown by the traffic to the sides and carried downstream onto the untreated surfaces.

A secondary clean-up is required to be performed three to five days after construction, but the contractor generally will sweep the next shift, and succeeding shifts, to pick up the shed material.

We hope that this helps to answer your concern.